Description

What Is A Test and Drain Valve?

What Is A Test and Drain Valve?

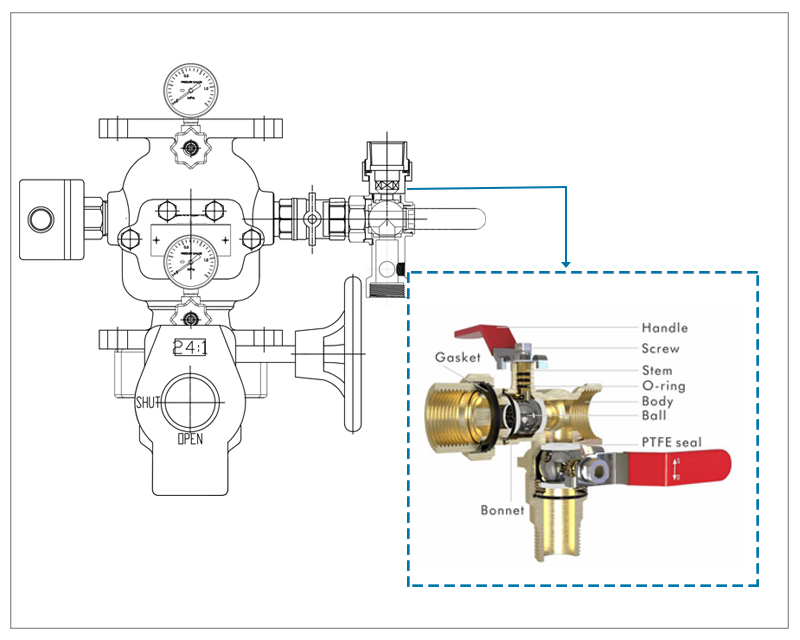

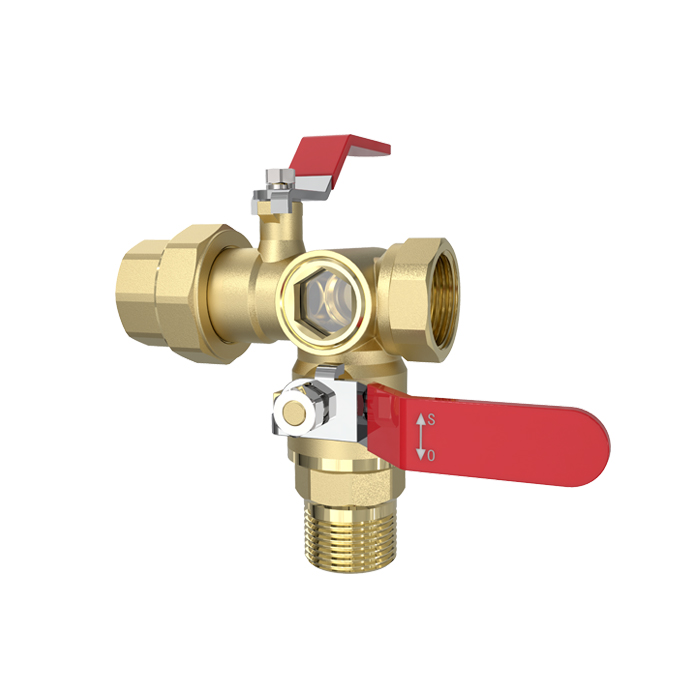

Test and drain valve is one kind of 3 way ball valve which has the function of testing, draining and closing the water flow at different status. It is used in firefighting alarm valve system. Compared with other drain valve, it includes double sight glasses to observe and confirm liquid flow through sight glass when open or close the valves.

It offers one step to resolve multi -requirements on the installation and maintenance of wet pipe fire sprinkler systems.

Materials & Feature of Parts

Materials & Feature of Parts

- BodyThe valve’s body is made of brass (C37710), which has excellent cutting performance, wear resistance and high strength.

- Valve’s NutThe valve’s nut can be made of brass (C37710) or low carbon steel (SM20C). When the low carbon steel material is used, the surface shall be chrome plated for anti-corrosion treatment.

- Sight GlassThe material of the sight glass is transparent explosion-proof plastic (PV), which has the good performance of corrosion resistance and pressure resistance.

- Soft Sealing PartsThe O-ring and gasket used for the sight glass and connecting nuts are made of silicon rubber in superior elasticity, and the other soft sealing materials are made of EPDM.

- Valve’s Sealing SeatThe valve’s sealing seat is made of PTFE and the valve ’ s ball is made of brass in chrome plating, which has good lubricity, sealing, wear resistance and corrosion resistance.

- Handle and ScrewThe handle is made of steel plate (Q235) in chrome plated.

The screw is made of stainless steel (S304) in anti loosening standard.

Product Feature

Product Feature

- It offers multi functions to open/close/test/drain the valve to control the water flow based on different status.

- The sight glass structure makes the water flowing visible.

- Forged brass process and engineered designed structure make the products in good resistance of compression, torsion and fracture.

- 100% integrated leakage and explosion test under 20 bar provide strong support for quality.

- High precision machining, top quality finish, make the valve’s quality stable and reliable.

- Professional engineered designed and produced, to give out excellent performance.

Product Performance Assurance

Product Performance Assurance

- Pressure Resistance TestThe valve must be no leakage, deformation, damage and other problems when the product is kept under internal pressure 1MPa (air pressure) or 2.5MPa (water pressure) for 1 minute.

- Operation TestWhen open or close the ball valve, the valve must be operated smoothly and steadily under the fluid pressure of 0.1 ~ 2.5MPa.

- Water Leakage TestClose the valve completely, the valve must be no leakage when max presure (1.4MPa) is applied at the inlet side

- Flow Test

The flow rate of this valve measured under 0.1MPa (1kgf / cm2) must be within 80 (±4)L / min.

Reviews

There are no reviews yet.